Intelligent Manufacturing: CISAI Tech creates China’s first 5G+AI-based intelligent management system

Date:2022/2/25 Source: CISDI

CISAI Tech, part of CISDI Group, has successfully put a 5G plus AI tech based steel interfacing management system online at Baosteel WISCO in China’s Hubei Province.

The first of its kind in China, the interfacing management system applies 5G and artificial intelligence tech to the steel sector.

Taking advantage of 5G network’s large band width, short time delays and wide connectivity, it breaks ground in high-quality data transmission at mobile and edge ends in complicated industrial conditions.

Five applied settings have now been implemented at WISCO’s hot metal and liquid steel interface management - for real-time positioning and tracking, equipment online monitoring, transport control, edge computing data return and railway crossing safety control.

The system will enable autonomous/unmanned hot metal transportation between the ironmaking and steelmaking plants, which will further enhance the plant’s productivity and safety and achieve cost savings.

● China’s first steel “Information High-speed Railway” put online

The CISAI Tech-built 5G+AI intelligent interfacing management system has achieved the first and largest operation of an Information High-speed Railway at a steel enterprise.

CISAI launched in June 2021 and by the first week in November that year, it had upgraded intelligent systems for WISCO’s five blast furnaces, four meltshops, 20 hot metal transport locomotives, 67 torpedo ladle cars, 100 open-top ladles and 12 level crossings, and had built an intelligent control system for the plant’s 400-plus rail lines.

Intelligent transformation brings about marked optimisation – a 20 per cent reduction in manpower, a 10 per cent increase in hot metal transport efficiency and a 10 deg C decrease in hot metal temperature drop at the hot metal and liquid steel interface.

A direct economic benefit from more efficient transportation is estimated to be around US$ 6.30 million.

● iSmartMC interfacing management system enables flat management and intelligent scheduling

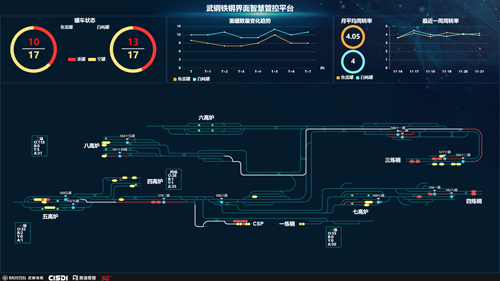

CISAI has developed an iSmartMC interfacing management system to enable flat management in hot metal, transport and liquid steel procedures and intelligent scheduling of hot metal production. The integrated information tech applied platform covers all flows and all factors at the interface.

Intelligent model and algorithm and intelligent information collection methods address the issues often experienced at a conventional interface – offline management, inaccurate and delayed collection of production data, unlinked communications between upstream and downstream procedures, unsmooth scheduling and limited transport efficiency.

The intelligent control centre for WISCO’s hot metal and liquid steel interfacing management

On a daily basis, a furnace operator places an order via a simple click of a mouse when the blast furnace is about to tap, immediately, summoning an autonomous locomotive loaded with a hot metal ladle to the taphole.

The ladle aligns itself with the taphole and receives hot metal. The autonomous locomotive then drives to the downstream steelmaking plant, all rail line switching and railings operating automatically.

● PanGoLIP smart industrial logistics platform - the interfacing brain

CISAI has developed a PanGoLIP smart industrial logistics platform, based on full-process intelligent tracking and status management.

It is the interfacing’s intelligent scheduling system and works like an AI brain – performing core automatic functions in hot metal distribution, path planning, microcomputer interlocking control, crossing opening and closing, and performance result generation.

WISCO has a history of over 60 years and its railways and crossings between the ironmaking and steelmaking plants are complex. Interfacing management requires highly complicated settings for implementing intelligent control.

A screenshot of WISCO’s intelligent scheduling system at hot metal and liquid steel interface

● 5G plus tech lays a solid foundation for autonomous hot metal transport at the interfacing and also makes transmission of mobile and edge data easier

CISAI’s 5G plus tech application at WISCO has helped to upgrade the plant’s hot metal and liquid steel interfacing intelligence.

The highlight 5G tech and its applications are:

✔ 5G plus integrated positioning:

The locomotive positions at various conditions are tracked in real-time and can be precisely controlled and intelligently coordinated. Regional production management levels have been greatly improved.

✔ 5G plus crossing safety control:

Railings at the rail crossing are automatically opened and closed. A video view of the crossing is uploaded to the locomotive system. Safe crossings are ensured.

✔ 5G plus online monitor of equipment status:

The locomotive’s sensor dynamically uploads its data to the control system, providing data support for implementing intelligent ops management.

The green, intelligent hot metal locomotive, travelling on the railway at WISCO, with multiple 5G plus tech applied

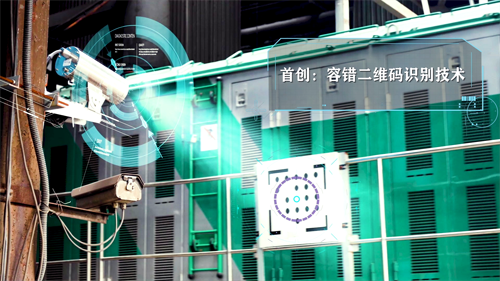

● FTIV – innovative tech for ladle code tracking and identification

FTIV – industrial fault tolerance visual identification tech - was developed by CISAI for WISCO’s hot metal ladle.

A breakthrough in encoding and decoding technology, FTIV combines QR code-based identification with deep learning. Accurate identification is achieved even in complicated, unfavourable conditions such as bad weather or poor light.

Correct identification of the ladle code is required throughout its application process, from the receiving of hot metal to its transportation by rail and its handling at the steelmaking plant. It is an important part of the hot metal and liquid steel interfacing process.

However, conventional identification methods can be marred by long-term exposure to high temperatures, heavy dust and hot metal splashing, leading to inaccurate readings. CISAI’s FTIV can correctly identify the ladle code with up to 60 per cent of staining present.

Coordinating with 5G edge computing data return, the FTIV performs with greater efficiency and saves operating costs.

The FTIV, an innovative product for identifying hot metal ladle codes, has been applied successfully at WISCO

● CISDI-WISCO innovation wins gold in national 5G application contest

CISDI-WISCO’s 5G plus interfacing management system has won first place in a national 5G application contest.

The awards, held by the Ministry of Industry and Information Technology, described it as an “innovative application and practice at a 5G plus fully-connected steelworks”.

This is the second time CISDI’s intelligent developments have been recognised by the industry. Its Shuitu Cloud industrial internet platform was awarded first place at national industrial internet contest

The company’s platform and product is playing a leading role in advancing digital transformation and building smart steel factories throughout China.

Aligning hot metal and liquid steel production tempo and output and the scheduling and dispatch of hot metal are key challenges at the ironmaking and steelmaking interface. Solutions encompass production organisation, scheduling control, operational process, production equipment and transport routes.

CISDI’s 5G plus AI interfacing management solutions have helped WISCO achieve its major goal of improving interfacing productivity.

They feature in WISCO’s 5G plus industrial internet demo park, which is comprised of intelligent logistics, production control, digital equipment, energy and environmental management, quality control and intelligent security.