CISDI – tech lead for advancing global blast furnace ironmaking development

Date:2022/8/22 Source: CISDI

CISDI’s 60-year history is studded with innovation-driven achievements in blast furnace ironmaking.

The company’s ironmaking core tech and equipment has played a lead role in assisting global steel producers reliant on blast furnaces and basic oxygen furnaces.

CISDI has been relentless in its vision to integrate the internet of things, big data and artificial intelligence into blast furnace construction, production and operation.

Many new, greener and smarter blast furnaces have been built thanks to CISDI’s solutions and services, and are now spearheading the advancement of higher standard steel production.

Achievements

- Over 220 blast furnaces have been designed and built around the globe by CISDI, in a wide range of volumes and profiles.

- CISDI has designed and built many of the world’s mega blast furnaces, with volumes of over 4,000 cubic metres. Reference projects account for 65 per cent of China’s market and 35 per cent of the world’s.

- CISDI opened up a new dimension of theoretical study for modern blast furnace smelting – advocating the building of a high-efficiency, low-consumption and long-campaign blast furnace with a bosh gas indicator at its core.

- High-efficiency, low-consumption mega blast furnace critical tech created by CISDI has enabled large blast furnaces to operate with greater stability, super-efficiency and reduced fuel consumption.

- CISDI was the first to export a Chinese-made blast furnace system.

- CISDI experts have chaired preparations for multiple national standards and monographs, advising on designs and constructions.

- The company’s development of a blast furnace intelligent management system, and successful applications of its centralised control, simulation and big data mining expertise, are pushing China’s ironmaking to new digital, intelligent levels.

- 40 awards for outstanding designs, five gold medals and five silver medals have been awarded to CISDI in nationwide Chinese evaluations.

Star projects in China

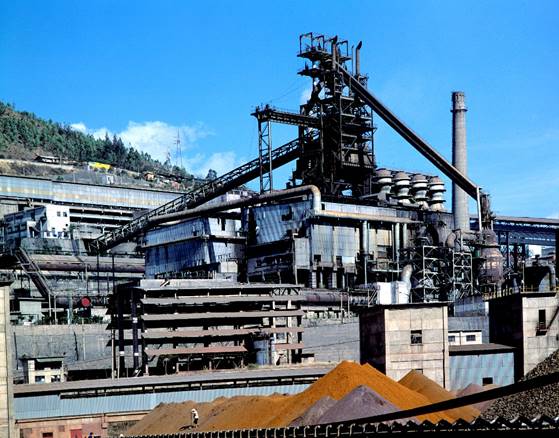

✧ Pangang BF4

In 1965 CISDI undertook the master-design of blast furnaces for Pangang’s plant in China’s Sichuan Province. Dubbed the ivory sculpture steel plant, all construction was adapted to the area’s multi-layered geological conditions.

The BF4, with a volume of 1,350 cubic metres, made the impossible a reality: for the first time, a conventional blast furnace was able to smelt vanadium-titanium magnetite.

This project won two major accolades in China - a national Outstanding Design award and first place in a national Technological Inventions award.

The Pangang blast furnace 4, designed by CISDI

✧ Baosteel large, modernised BF cluster

Since 1978, CISDI has master-designed multiple large blast furnaces at Baosteel in Shanghai. These furnaces were China’s first to be modernised and played a role in the transition of the country’s ironmaking tech from import-reliant to independent.

CISDI’s contributions to Baosteel blast furnaces:

- BF1 first started up in 1985 and was rebuilt in 2009: China’s first 5,000-cubic-metre-level blast furnace, it set the highest Chinese-made standards at that time.

- BF2 was started up in 1991 and rebuilt in 2006.

- BF3 was started up in 1994 and rebuilt in 2013. It was the first large blast furnace independently designed and built by the Chinese, achieved the longest service life of 19 years and hit record production figures - more than 15,000 tonnes of hot metal output per cubic metre of furnace volume.

- BF4 was started up in 2005.

The blast furnace cluster, designed by CISDI at Baosteel Shanghai

✧ Benxi Steel’s BF 8

CISDI was the EPC-based service provider for blast furnace 8 at Benxi Steel in China’s Liaoning Province. The 4,000-cubic-metre-level furnace was the first of its kind in China.

Benxi Steel’s BF8

✧ Baosteel Zhanjiang’s BF cluster – each with a 5,000-cubic-metre volume

CISDI provided package supplies for blast furnace 1, 2 and 3 at Baosteel Zhanjiang in China’s Guangdong Province.

Now operating with state-of-the-art performance indicators, they set the global standard for green, efficient blast furnaces.

The large blast furnaces at Baosteel Zhanjiang, supplied by CISDI

✧ Zenith Nantong Steel’s BF cluster

CISDI is building blast furnaces at Zenith Nantong Steel in China’s Jiangsu Province, to an EPC mode.

The furnaces will be future-oriented, green, smart, high efficiency and long-campaign. They will make Zenith a major support for the implementation of China’s strategy for integrating developments in the Yangtze River Delta, and optimising regional layouts for the steel sector.

One of Zenith Nantong’s CISDI-built blast furnaces is now in operation

✧ Baowu Shaogang’s BF

Shaogang’s blast furnace 7 is the world’s first intelligent blast furnace.

It heralds a new era for transforming conventional ironmaking to artificial intelligence levels.

The furnace was transformed with the addition of CISDI’s digital design and operation, visualised production and intelligent decision-making tech.

A “virtual foreman” oversees ironmaking production via digital, intelligent methodology. All operation and production is in the hands of a centralised control centre.

Shaogang’s digitally transformed BF7

Star projects around the world

✧ Gerdau Acominas BF2 in Brazil

In 2007, CISDI package-supplied a blast furnace 2 to Gerdau Acominas in Brazil. It was the company’s first tech and equipment export of a large blast furnace.

Successfully operating – the 1,750 cubic metre BF2 at GA in Brazil

✧ Formosa Ha Tinh Steel’s BFs in Vietnam

Formosa Ha Tinh Steel’s blast furnaces 1 and 2, each 4,350 cubic metres in volume, were built by CISDI to an EPC mode.

They are the largest of their kind in the world to be built over the past decade.

CISDI was China’s first exporter of a full system for large blast furnace ironmaking, ranging from the planning and design of the furnace to its supplies, project management and operations management.

The FHS blast furnace project won CISDI a Chinese gold medal for Outstanding Engineering.

BF 1 and 2 at FHS in Vietnam, built by CISDI

✧ TATA Kalinganagar Steel’s BF2 in India

CISDI is the designer of the world’s largest Greenfield blast furnace – the BF2 at TSK in India. The 5,873-cubic-metre blast furnace was entirely designed and delivered using a 3-dimensional modelling system.

CISDI’s digital design deliverables broke through the long-held domination of European suppliers.

A model view of the CISDI-designed BF2 at TSK

✧ ASSB BFs in Malaysia

ASSB’s blast furnace 1 and 2 are based at the Malaysia-China Kuantan Industrial Park in Malaysia. CISDI designed and supplied them, with entirely Chinese-made equipment.

The furnaces are the most advanced and the largest ones in Malaysia.

The ASSB BF, a demo of Belt and Road Initiative projects