Intelligent Manufacturing: The AI Eyes have it! CISDI’s visual smart perception tech for ferrous metallurgy is officially world-class

Date:2023/10/20 Source: CISDI

CISDigital AI Eyes - visual smart perception tech for ferrous metallurgy - has been labelled ‘world-class’ by the Chongqing Academy of Science and Technology.

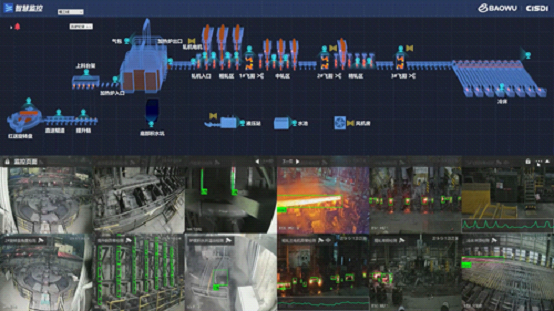

The AI Eyes cameras work in tandem with a control platform.

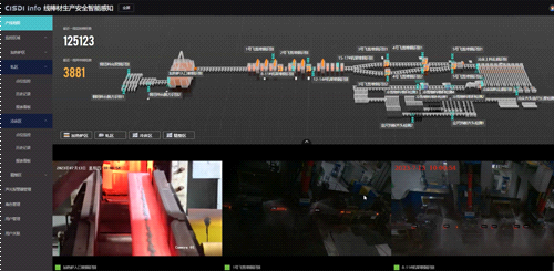

A smart algorithm model group is applied to enable image identification and analysis at all steel production settings and implement BOF flame identification, smart dust collection control and smart belt conveyor checking.

This tech has been applied to the full ferrous metallurgical process - from ironmaking to steelmaking, continuous casting, rolling and final product warehouse - at a number of China’s medium and large steel plants.

Baowu Shaogang and Chongqing Steel, Pangang, Baotou Steel, Yongfeng Steel, Maanshan Steel and Hanzhong Steel are witnessing its advanced technological results.

CISDigital AI Eyes generates moderate or high-definition images during complicated steel manufacturing processes. Thanks to its rendered video streaming and deep-learning model, Eyes can identify what images are required with high accuracy and within 150 milliseconds.

Using flame’s status identification as an example, the Eyes algorithm identification is achieving an accuracy rate of over 99.5 per cent.

Remarkable economic and social benefits have been created by this tech, which has been awarded 69 patents, including 45 for invention, and has been the subject of 15 published theses.

Its standout solutions for achieving higher safety standards during steel production and greater quality, efficiency and intelligence gives CISDigital AI Eyes huge market prospects.

This application setting shows assisted decision-making via smart production line perception

An application setting showing bar and wire-rod rolling line smart perception for ensuring safe production

Dust collection smart control

Belt conveyor smart regular checking