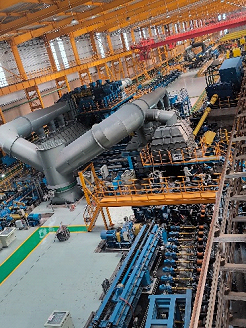

Main rolling line is hot commissioned at Changqiang Steel’s special tube

Date:2024/7/31 Source: CISDI

A groundbreaking rolling line built by CISDI in China’s Jiangsu Province has discharged its first product with an outer diameter of 127 mm off the cooling bed.

Changqiang Steel’s new line, built by CISDI to an EPC mode, will be the first smart small-calibre production line in China and will operate with centralised control.

Three-dimensional digital design methodology and the CISD-QINGZHU smart construction platform were applied.

While developing the core tech and equipment, CISDI implemented omni-bearing controls on quality, safety and schedule throughout.

This line will produce the widest specifications in China and meet the demands of numerous markets.

Its production will include tubes for petroleum oil casing, ultra-supercritical boiler units, corrosion-resistant pipelines and high-precision machinery, ranging in ODs from 32.0 to 114.3 (140.0) mm, wall thicknesses of 3.5mm to 12 (16) mm and lengths of 6.0 to 13.0m.

Important features encompassed in this intelligent, digital, green and competitive special steel tube rolling benchmark:

Equipment – To ensure key performance indicators such as production piece rate, dimensional accuracy and roll change time are achieved, the line features the following equipment: World-class high-precision vertical Piercer Mill

w High-efficiency and optimum 3-roll Mandrel Pipe Mill

w Large-tension, low-cut-loss Stretch Reducer

w High-rigidity 6-hi Straightener.

Energy reduction – The following have been applied to reduce energy consumption:

w Regenerative annular reheating furnace

w Innovative hydraulic servo energy-saving system

w Polymer heat-resistant porous board dust collector.

Smart manufacturing – combining cloud computing, industrial internet, big data and AI expertise with production scenarios will centralise control of tube rolling and achieve smart production and smart operational and management control.

Hot commissioning of the first special steel tube at Changqiang Steel

|

The high-precision vertical cone-type Piercer, which is bringing about high-quality products and speeding up production pace

|

The super Assel mill is creating higher precision and yield of products

Large-tension reducing mill featuring a single-stand drive and low cutting losses: achieves a reducing ratio of higher than 70 per cent and enhances 1 to 2 per cent of metal yield |