CISDI Digital Twin boosts digital steelworks

Date:2019/10/15 Source: CISDI

CISDI Digital Twin boosts digital steelworks

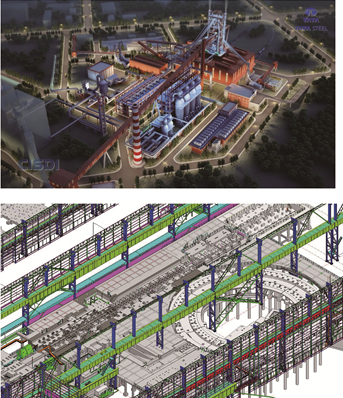

CISDI Digital Twin expertise is BIM based and a digital design with a

complete 3D model and project database.

A window connecting the physical plant and the digital domain, Digital

Twin provides a digital model for the plant and production line, effectively laying

the foundations for the building of smart plants and network-based plants in

the future.

CISDI applies the internet of things to integration of production data

with engineering and produces a digital plant which corresponds with the real

plant.

With the aid of augmented reality, digital information can be directly

superimposed on the real plant. This achieves digital managements of equipment patrol checks and maintenance,

operator training assistance, production status visualization, and virtual, remote and centralised

control.

CISDI Digital Twin is being applied to India’s TATA Steel Kalinganagar blast furnace 2 and Australia’s Liberty Primary Steel Whyalla PCI plant.

CISDI’s digital design delivery for TATA Steel Kalinganagar’s blast furnace 2, the world’s largest greenfield blast furnace under construction to a volume of 5,870 cubic metres

CISDI has built a complete 3D model and database for this project. To

help TATA Steel achieve digital management of the engineering, construction and

production, CISDI has integrated and interlinked the model, drawing and

documentation data with the production and operational data.

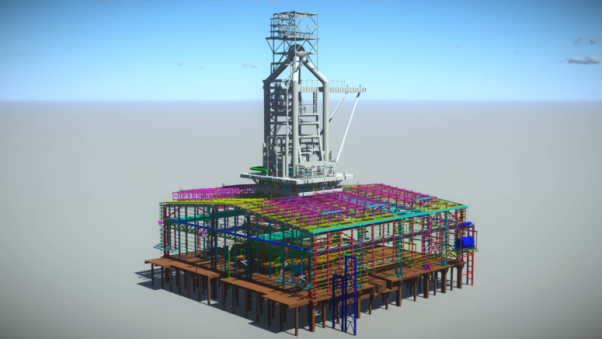

CISDI’s digital design delivery for Liberty Primary Steel Whyalla PCI

plant involved the building of a complete, accurate 3D model and database,

which will enable a modular construction