Key dates in the story of CISDI

Date:2019/1/25 Source: CISDI

Key dates in the story of CISDI:

1958: In response to China’s call for industry to aid

the development of its southwestern provinces, the Anshan Ferrous Metallurgy

Design Institute was relocated to Chongqing and renamed Chongqing Ferrous

Metallurgy Design Institute. It was run by the Ministry of Metallurgical

Industry.

The office

building for the former Anshan Ferrous Metallurgy Design Institute in Anshan.

Sited in the Liaoning Province, Anshan was known as the cradle of New China’s

steel engineering

1965: A team of more than 70 engineers were sent to

Panzhihua Steel (Pangang) to carry out field design and services. They remained

until 1974, by which time Phase I of China’s first self-built large steel base

was largely complete.

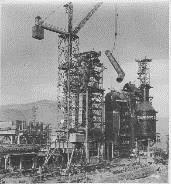

The Pangang

blast furnace during its construction

1978: At the beginning of China’s period of economic

reform and opening up to the outside world, a revolutionary steel project, Baosteel

Shanghai, officially broke earth. It was China’s first modernised large steel

enterprise and CISDI were responsible for the general design.

Baosteel

Shanghai‘s ground-breaking and mobilisation ceremony

1992: To reinforce collaboration

between

engineering and production, a decision was taken to allocate the Chongqing

Ferrous Metallurgy Design Institute to Baosteel Shanghai.

1998: Management of the Chongqing Ferrous Metallurgy

Design Institute was taken on by the China Metallurgy Construction Group and

renamed the Chongqing General Iron and Steel Design & Research Institute.

The event

staged for joining Baosteel Shanghai

2001: Chongqing General Iron and Steel Design &

Research Institute was awarded the EPC-based contract for Xinyu Steel’s Basic

Oxygen Furnace. At the time it was China’s biggest investment in a single unit

metallurgical EPC project. It was also the first time a design institute had

been tasked with building a steel plant on an EPC basis.

Xinyu Steel’s

basic oxygen furnace in operation

2003: Chongqing General Iron and Steel Design &

Research Institute handed its core businesses to the newly incorporated CISDI

Engineering Company.

The opening

ceremony for CISDI Engineering Company

2005: CISDI Engineering Company won the bid to

create the 1,750m3 blast furnace for Gerdau Acominas in Brazil on an

EP basis. At the time, this was China’s largest metallurgical package supply

export project.

The Gerdau

Acominas 1,750m3 blast furnace is running smoothly in Brazil

2010: CISDI launched its first overseas branch, CISDI

Brazil (MCC-CISDI Projetos Industriais do Brasil Ltda)

2011: CISDI Group Co., Ltd. was created. CISDI Engineering Company

became one of its subsidiaries and began to diversify its business portfolio.

The opening

ceremony for CISDI Group Co., Ltd.

2014: CISDI opened its UK subsidiary in Sheffield,

creating a bridging link for the company’s European and American marketing.

Representatives

of CISDI Group and the UK team, pictured at the CISDI UK building

2015: CISDI was awarded the contract to engineer the

new blast furnace 2 for TATA Steel’s KPO Plant in India, the largest of its

kind in the world.

The year also

saw the release of the CISDI-developed technology Nudge+, the first

self-sufficient internet platform product for mobile office.

An artist’s

view of the CISDI-designed blast furnace 2 at TATA Steel’s KPO Plant in India

2016: Baosteel Zhanjiang’s Phase I was completed.

CISDI was the master designer and the predominant service provider for

Zhanjiang Steel. CISDI has since provided E/EP/EPC services for Zhanjiang

Steel’s stockyard, ironmaking, continuous casting and hot strip mill plants. CISDI is also helping Baosteel to achieve its

goal to build Zhanjiang Steel as a world-class green carbon steel prime

production base.

Also this year,

construction began at ASSB MCKIP in Malaysia. CISDI was responsible for general

design and plant design, plus package supplies of most of the equipment. CISDI

is contributing to the Belt and Road Initiative.

Baosteel

Zhanjiang’s green steelworks

2017: CISDI was awarded a national Chinese scientific

and technological progress prize for its recently concluded research and

development of High-efficiency, Low-consumption Mega Blast Furnace Core

Technology and Application.

This year the

blast furnace 1 of Formosa Ha Tinh Steel (FHS) in Vietnam was successfully

started up. CISDI had built it - its first mega blast furnace overseas - to an

EPC mode. The project is seen as an outstanding example of international

cooperation for production and equipment supply on the Belt and Road route.

Also in 2017,

CISDI Group opened its USA subsidiary in Pittsburgh.

The application

of the CISDI-developed High-efficiency, Low-consumption Mega Blast Furnace

2018: CISDI set out its agenda for a journey of innovation

- it aims to boost intelligent and big data developments to upgrade the

steel industry.

The

CISDI-developed Q-Touch 2.0 went on show at the Smart China Expo in 2018