Specialised Topic: METEC 2019 - a great place to showcase our skills, say CISDI bosses

Date:2019/7/30 Source: CISDI

Hong Dai, head of Metals Mining Business Dept.

for CISDI’s Consulting Business Division

How

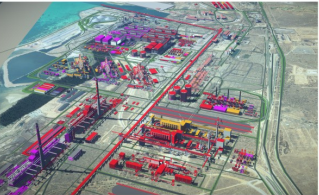

five-flow systematic solutions enhance plant-wide competitiveness

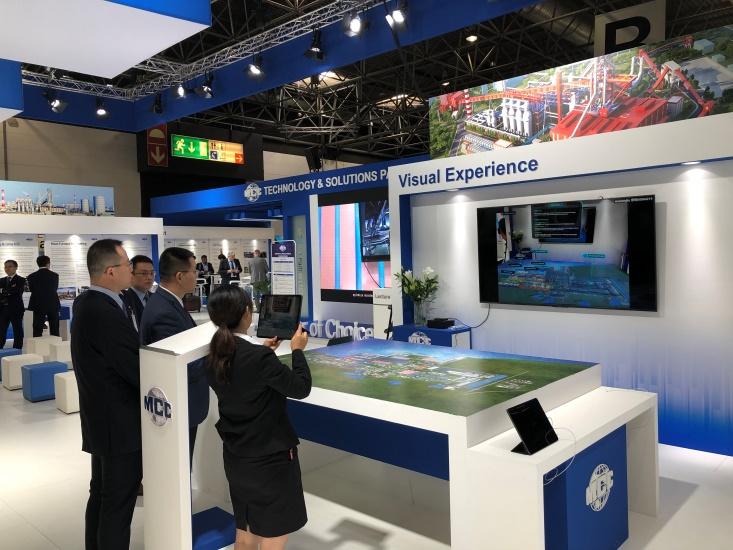

Augmented Reality enabled me to take METEC

visitors on a dynamic visual journey around Baowu Zhanjiang Steel.

Over 100 people marvelled at the experience

and learned how CISDI had improved the steelworks’ competitiveness by studying

the plant’s five flows - iron flow, mass flow, energy flow, information flow

and emission flow - and designing a steelworks master plan around them which

would be more competitive, economical and better for the environment.

I used AR to take visitors on a ‘tour’ of the

plant’s general layout and through a dynamic simulation of the five flows and

how they had been used.

During my AR demonstrations I received

numerous interesting questions and comments.

A visitor from South Korea commented: “How

amazing! Can I try it? What are your core technologies?” and a visitor from

Japan wanted to know the maximum water recycle ratio and the designed iron

utilisation ratio.

An intrigued steelworks representative from

India revealed its plant had never attempted to recover blast furnace gas and

wanted to know how the company could benefit from gas recovery.

A visitor from Africa was particularly

impressed and enquired how CISDI’s technology could assist with the problem of

low-quality ore grade at the location of their steelworks, and reduce production

costs by using the five-flow concept.

A representative from a European steelworks

wanted to know if analysis of emission flow could guarantee a reduction in

emissions which would meet the environmental requirement.

More and more clients now appreciate the

significance an optimised general layout design, or master plan plays when

creating better values for steel.

In our opinion, pursuing cost competitiveness

is crucial to the future of steel and CISDI’s general layout design places it

as top priority, from front-end planning to downstream designs.

We use a multi-dimensional analysis method to

evaluate the systematic investment and propose an optimised design which will

control the entire investment cost.

In addition, we study the plant-wide

comprehensive cost, individual plant continuous cost and the influence

important factors can have on costs.

We find out the variations in manufacturing costs per tonne of steel and the reasons for those variations. Based on those results, we then propose an optimised general layout which would enable the steelworks to run at its most cost-competitive production levels.

Green and intelligent manufacturing are other

major commitments for the steel industry and given great emphasis in our

general layout designs.

CISDI is conducting a feasibility study report and plant upgrades for LPS Greenfield 10Mt/a steelworks, the largest steel complex to be built in Australia

A CISDI’s representative operates the AR for the 5-flow expertise for Baowu Zhanjiang Steel